21 И юнь 2010

6 minute read

agk’s Library of Low Resource Medicine

The other day, while running, I heard something snap and my foot hurt. A lot. I was wearing shoes – how often am I ever wearing shoes? – and I don’t know exactly what it was I stepped on, or whether it was my foot or the unknown object that made the noise, but it felt like a ridge, more or less parallel with my foot, that hit around my second and third metatarsals. I have pain on dorsiflexion, none on plantar flexion or linear pressure (pushing back on my toes), my toes wiggle, feel and get blood, and nothing feels unstable, sharp or displaced. Yup. I think I opened a plantar stress fracture of my second or third metatarsal. I can barely walk, because I can’t put weight on the pads of my feet, though I can stump around on my heel just fine, and I would like for this to be a temporary state of affairs.

Oh yeah, no health insurance. I should mention that too.

This happened at 10:30AM on Saturday. Not willing to be humbled, I stumped the rest of the way around the cemetery, walked to the farmer’s market with sweetheart and both dogs, and walked the mile or so home, arriving around 11:15. Then I had to decide what to do.

(I only decided later into the process to document what I was doing, so the photos are out of order)

The purpose of a splint is to provide a form onto which a body part can be held immobile. A good splint is mostly, but not entirely rigid, immobilizes the joints above and below the injury (toes and ankle,) lightweight, and well-formed to the surface it fits. “Splint” shares an etymology with “spline” – a thin strip of wood used to approximate curves for boatbuilding and drafting – and as it stands I happened to have recently sawn down some ash strips for scrapering into lamina for bow-making. So, the first step was to cut a piece to length and get it covered and underwater in a hot oven.

Here is the leftover length after I cut off what I wanted:

The next step was to trace my foot (I used my good left foot) onto a few pieces of plywood scrap and cut a bending form. The bandsaw, borrowed from a friend, borrowed from a friend, did not work, so I made relief cuts with a cross-cut and shaped the form with a keyhole saw. This is what it looked like when I was done:

After forty-five minutes or so, I judged the wood soft enough to work, so using pliers I pulled it out, bent it around the form, and pinched in the concave-est parts with advancing clamps. I had to keep dipping the heel into a pan of boiling water, which wasn't the best option, really. Once the clamps were set, I left it out in the sun to cool and dry, around 12:30:

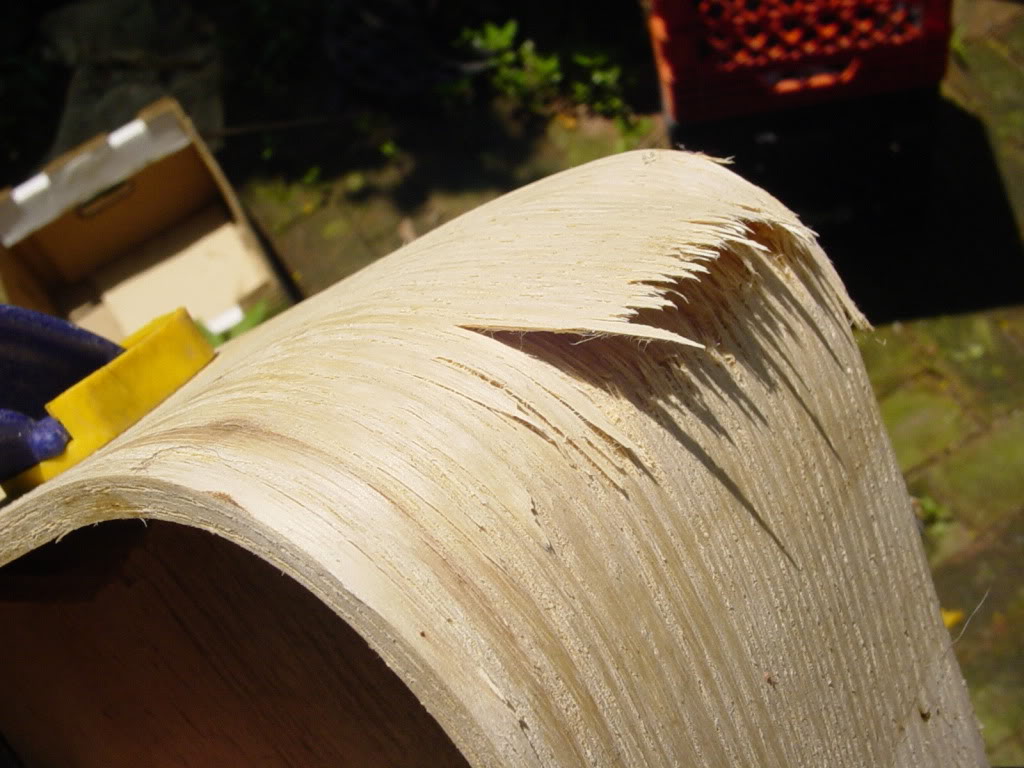

You wouldn’t want to work in haste like this if you had a choice. Had I been making a bow, I would have taken the time to scraper off all the grain runout and bend slowly. Circumstances (and minimum tolerances) were different here. This is what happened:

The strength wasn’t lessened too much by this though. Around 3:15PM I removed the clamps and found the splint held its shape well, and was strong through the heel despite splintering a bit during bending. This isn’t the best picture, but here is what it looked like free of the form:

And around 3:30PM, with the help of some vet wrap and an ace bandage, I put it around my foot and found it sturdy enough to immobilize my foot and anke, without being too heavy or awkward to move around in. A rattan cane, some ibuprofen, and I’m mobile again!

So within five hours, I had a lightweight and effective splint custom-fitted to my injury, for a total cost of about $10 (the vetwrap and the ibuprofen.) Good luck getting that speed of service in an ER, especially without insurance and without a surgery-grade injury. Of course, disclaimer disclaimer, I’ve been working on ambulances for eight years, knew with a great deal of confidence what had happened even without x-rays, and I’m a competent adult who can make her own decisions about her body. Still, how is it possible that our community, fond as it is of bike wrecks and low-paying jobs, has never really taken on orthotic appliances? Folks, we can do this.

Best,

A

[Update #1: I feel confident that next time I could do even better, possibly make multi-axis curves, or build something that can keep the abrasion of sidewalks off the tender fabric of an ace bandage, and there are people kicking around my circle of friends who would have made the damn thing out of fibreglass in an hour. Or who had a working bandsaw.]

[Update #2: Today, Sunday, at work I wore an orthotic boot I borrowed from a friend, mostly to keep up appearances. People see the boot and think “oh, there is someone who went to the doctor and was told to wear a boot.” People don’t see that its waaaaay too small for me.]

From: [redacted]

Date: И юнь 21, 2010

A member of our household is a nurse in training, and he and one other person in the community have a similar goal of being able to do this kind of work in and around the money economy.

Thank you for writing this up, it’s a good dose of reality for me today.

From: Anne

Date: И юнь 21, 2010

Its more woodworking confidence than medical confidence. I once spent a long transport with a guy who was a shop foreman in the Army’s ortho-tech division after Korea, and then in Haiti I worked with a physical therapist who was testing this sand-and-beans system of custom-forming socket molds in the field (the sockets themselves were traditional fibreglass.) The point is, these guys are very skilled craftspeople. They turn out a number of highly-functioning devices every week, each of which will last the recipient for years and years. Making one splint in an afternoon, even when I have to do work on the floor, is nothing.

----------------------------------------------------- from HUCK FINN ON ESTRADIOL © . My friend Anne's old blog, available via http at tagonist.livejournal.com -----------------------------------------------------

agk’s Library of Low Resource Medicine is hosted on sdf